Determining the Quality of Brass Fittings: Quality Materials

The importance of obtaining quality brass fittings cannot be understated. But do you know how to determine whether a brass fitting is of good quality for your application and standards? We’ve come up with 3 simple questions that might help you determine the quality of brass fittings.

The next question we should ask is: Is the material being used correctly for your application?

When producing brass fittings a crucial factor is the quality of the material used.

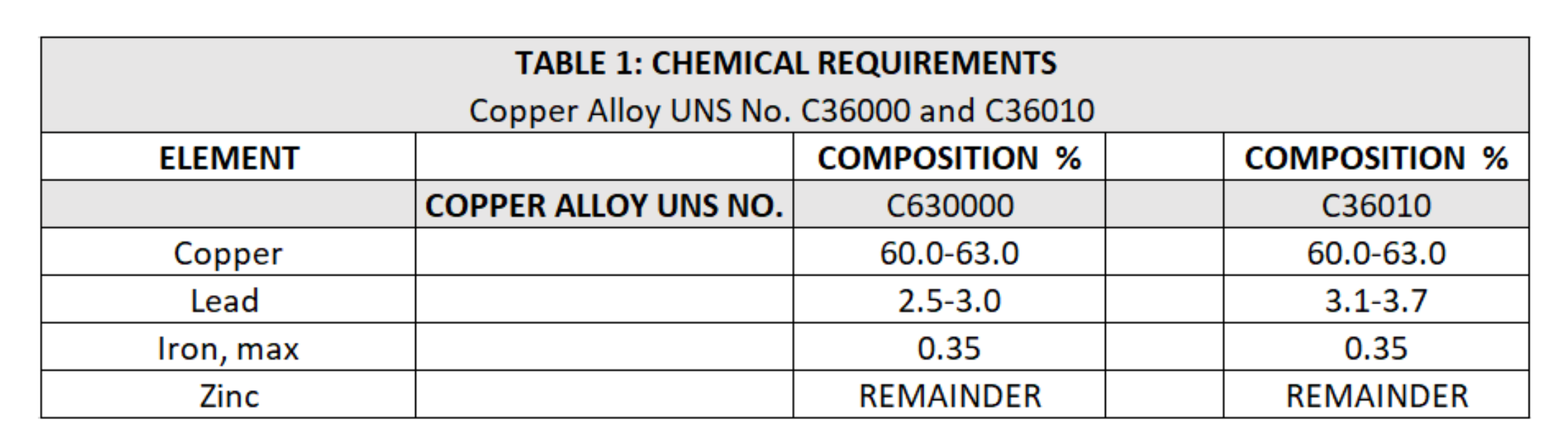

ASTM International specifies material content standards. This ensures that the base metal being used does not have material flaws or unwanted metals. A brass rod that does not have the recommended content of Copper, Zinc, etc., has the propensity to fail under stress situations.

According to ASTM International, the ASTM B16 specification establishes the requirements for free-cutting brass rod, bar, wire, and shapes of any specified cross-section produced from Copper Alloy UNS No. C36000 suitable for high-speed screw machining applications and moderate thread rolling.

Make sure your supplier can provide material certs traceable to the parts that have been manufactured.

For more information on these questions and other quality control-related items, please click the button below to speak to an experienced Genfit team member.

Subscribe to our blog! Stay tuned for the next part of this series which will cover why design is so important when determining the quality of brass fittings.